Gearbox technical discussion by Rallispec

Publié : lun. janv. 08, 2007 12:29 pm

Avec toutes les discussions ici au sujet des trannies, peut etre que ce text va interesser quelques uns d'entres vous et sera une bonne adition au forum "Transmission/Differentiel"

Kos

Kos

Thread original sur NASIOC click here!RalliSpec a écrit :

We seem to recieve a tremendous number of questions about WRX gearbox issues, gear oil recommendations, etc. I thought I would post an overview of some of these questions and provide answers based on our experience and research. I am sure that some of this info may be floating around in various places but perhaps it will help to have it compacted into a single thread.

Why did Subaru put a 5-speed gearbox into the WRX that is not strong enough? The answer is that it is strong enough for what they considered to be normal useage of the car. At standard power & torque output, with standard clutch, and grip levels provided by the standard tires the WRX 5MT is more than sufficient to hold up to even aggressive driving styles. What Subaru can be accused of, however, is providing a gearbox with insuficient safety margin to handle the degree of modifications a significant portion of the owners are making to their cars.

Why is the WRX 5MT gearbox weak? This origin of this gearbox design dates back more than 20 years. The original engineering criteria were probably a lot different than they would have been now or even 5 or 10 years ago. The biggest problem is the gear centerline spacing. The 5MT uses a 75mm gear centerline spacing. This is the primary limitation for producing gears with teeth large enough to handle big torque levels yet quiet enough for the general public and not wear out within the normal life expectancy of the car. Combine this with splash lubrication, a longitudinally split case, inexpensive material choices, etc. and it is clear that it is not going to support power levels not typically seen even on many so-called exotic sports cars.

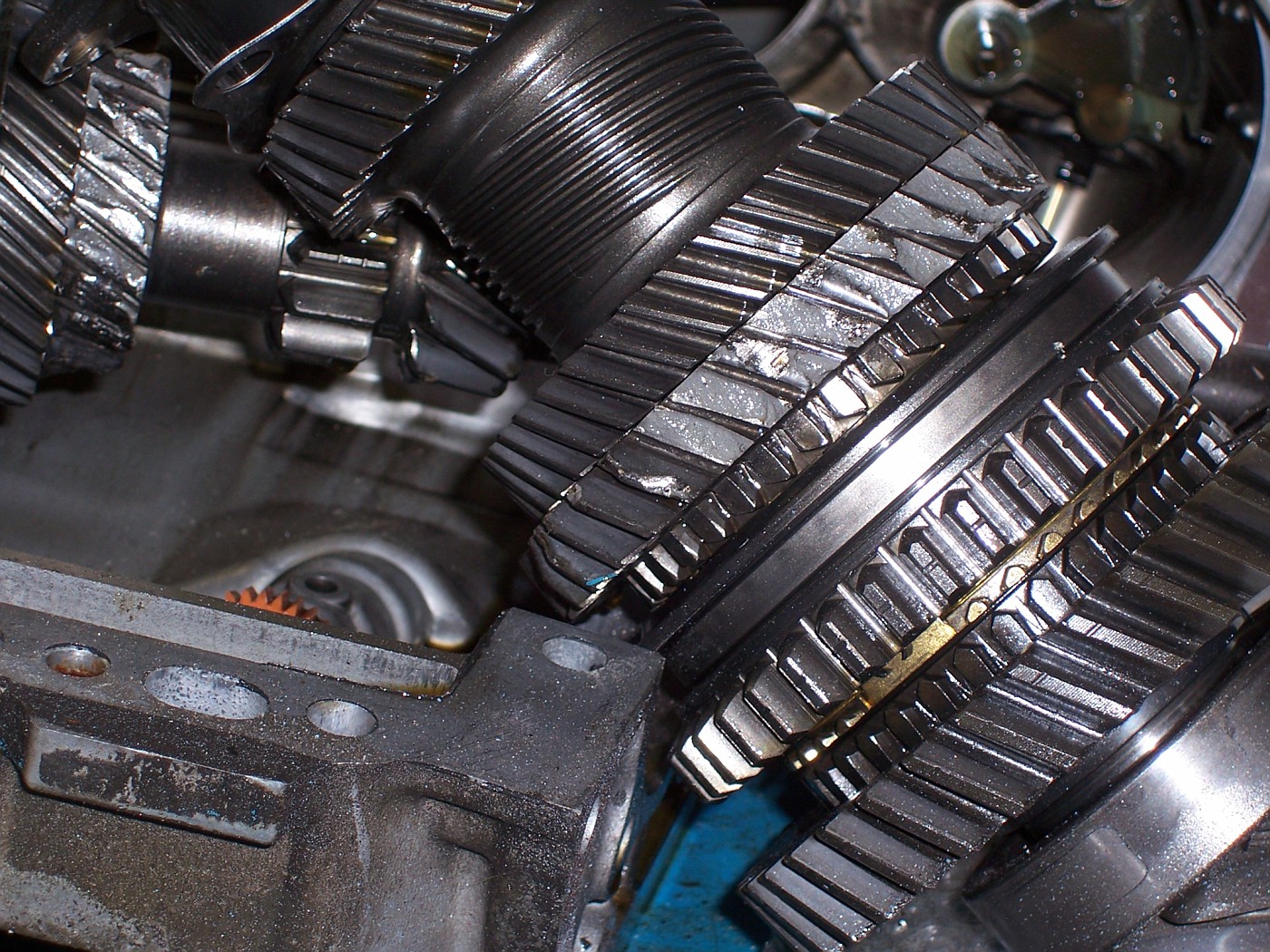

What is the exact cause of failure in these gearboxes? We've done some testing in this area. While many people have promoted case distortion as the cause of the failure (we were probably guilty of promoting this theory very early on)....strain guage testing of the case showed only a small level of distortion even at very high torque levels. While even a small amount of distortion is bad because it misaligns bearings and gears increasing friction and heat generation, it is not the main cause of failure. The main cause of failure is excessive gear tooth separation due to shaft flex. We found that at only 275lb-ft of input torque the gear tooth separation exceeded the recommended engineering limit for a helical gear profile. This separation occurrs because the mechanical leverage provided by the gears also creates a reaction force that wants to push the gears away from each other. The more torque you apply to the gears the more force there is trying to separate them. The input shaft is particularly thin so it can flex quite a bit. When the teeth separate the bending loads on the root of the tooth go up quite a bit. Ultimately the weakest tooth fails and creates a domino effect by wedging between the next set of teeth tearing them free and so on. It is very common to see every tooth on the gear torn clean off.

What can be done to strengthen the gears? The best option is to increase the root width of the teeth on the highly stressed lower gears. This is done by changing the gear tooth pitch. Tooth pitch is basically the number of teeth per inch of gear circumference. A comparison of RA and standard WRX gears will show a large difference on 1st and 2nd gears in this regard and a lesser increase on 3rd gear. Also, early WRX gearboxes (mid-2003 and earlier) had narrow (face to face width) 1st, 2nd, and 3rd gears. After mid-2003 the width was increased by 1mm on these gears and therefore matches the width of the RA and STi gears we sell. There are space limitations preventing further widening of the gears. The other thing is to alter material specification and treatments to improve either the ultimate strength or the fatigue life.

What about dog gears, aren't they a lot stronger? Most dog gears use a straight cut (spur) gear design instead of the helical gear profile used by Subaru. Spur gears are actually weaker than helical gears for the same width and tooth pitch. This is because there are fewer teeth meshed at the same time and the curve of the helical profile creates more surface area. However, replacing the synchronizers with dogs allows the manufacturer to significantly widen the gear widths so this loss in strength is reclaimed and then some. We've seen that some of the cheap aftermarket gearsets (dog or synchro) can be actually more prone to failure than an RA set. This is usually a result of insuficient heat treatment or excessively hardening the gears (creating a brittle gear not capable to absorbing high shockloads).

What is close ratio gearing? Gear ratios represent a ratio of the number of teeth on the driven gear to the number of teeth on the drive gear. A short gear (higher numeric ratio) creates a higher torque multiplication but at the same time requires the drive gear (driven by the engine) to spin very fast. So therefore a short gear ratio will provide a higher torque to drive the wheels and accelerate the car quickly but will require the engine to spin very fast (and it will reach redline very quickly). When you shift up the next gear is taller (lower numerically) so the torque multiplication is less but the engine speed decreases compared to road speed. A close ratio set means the numeric difference between the ratios (1st to 2nd, 2nd to 3rd, etc.) is reduced. Therefore when you shift the engine speed does not drop as much. The effect is to allow the driver to keep the engine operating in the optimum potion of the power band between peak torque rpm and peak hp rpm. Ideally for maximum acceleration you want to be able to shift a few hundred rpm after peak power and have the revs drop right to peak torque. However, if the engine has a wide torque band (as may be the case with a 2.5L w/ fast spooling turbo vs. a 2.0L with a big laggy turbo) then the need for a close ratio is not as important.

Why is the choice of gear oils so difficult for the 5MT? Two reasons. Number one is the fact that the front final drive gear is packaged inside the gearbox and shares the gear oil with the main portion of the box. The final drive gear is a hypoid gear design (tapered helical profile) and requires special additives to keep wear to a minimum (there are high loads combined with heavy sliding friction). On the other hand the synchronizers work best with a minimal level of these additives. Thus there are conflicting requirements. Number two is that when this gearbox is highly loaded it generates a lot of heat which is difficult to dissipate with just splash lubrication alone. This heat generation lowers the viscosity of the oil which also creates problems with the synchros (because to achieve a fast shift speed the synchro relies on oil drag between baulk ring and synchro cone to help match gear speed).

What gear oil should be used? Some people are recommending the use of GL-4 gear oil. GL-4 has a low level of additives mentioned above and therefore improves synchro performance. However, this is going to be at the expense of final drive gear wear. GL-5 has more EP additives which is better for the final drive but worse for synchro performance. Synthetic GL-5 oils tpically make this issue worse because of the properties of the base stock. Any synthetic GL-5 designed for "use with limited slip diffs" is going to be the absolute worst. To combat the heat issue, anyone running extended periods at the track or just putting long duration severe loads on the gearbox might consider running a 75W140 gear oil instead of 75W90. The gear oil should also be changed more frequently because the heat breaks down the oil and changes the properties.

What about GM Synchromesh gear oil? In theory this sounds like it should work very well because it was engineered for just this type of situation (synchros w/ hypoid gear). However, it was engineered specifically for GM synchro components which are not exactly the same as Subaru. Worth experimenting with though if you are having difficulty finding an oil that works well for you. It is important to note that GM synchromesh has a base stock similar to engine oil. It probably will thin out too much with high heat levels so for track day or competitive use its not ideal.

Do synchros wear out and are there upgrades available? Yes, the baulk ring portion (sometimes called synchro ring) of the synchronizer assembly is the wear item. Only a small amount of wear is enough to create issues. Forcing a very quick shift or forcing a shift when there is a large speed difference between road speed and shaft speed (like downshifting into the wrong gear) will accelerate the wear very quickly. In competition use it should be expected to replace baulk rings once or twice a season. If you drive your car every day like its a race car then expect to be replacing synchro parts. Unfortunately there are no upgraded synchros available for the 5MT that I am aware of. For the 6-speed STi gearbox a carbon-reinforced baulk ring is now being used on 4th, 5th, and 6th gears (which we can offer to '04-'05 STi owners who are having problems with synchros). It would be nice if a carbon-reinforced baulk rings were available to 5MT owners....perhaps there is a company out there that can produce a low volume run of them.

What about shot peening, cryo treating, microfinishing of gears? Shot peening helps with the fatigue strength by creating a compressive layer on the surface. Gear teeth are subjected to continuous load variations as the teeth engage and disengage from each other. Shot peening can improve life of the gears if the load levels are high but obviously will do nothing if you are exceeding the tensile strenght limit. Unfortunately, shot peening can distort the component in the process so it should only be done just prior to finish machining of the component. If done to a finished part then it may affect the fitment.

Cryo treating, although a controversial subject, has been shown by reliable sources to provide benefits to components such as gears. One effect of the cryo treatment is stress relieving. The gears are heat treated and then stress relieved by the factory but very often the level of stress relief is incomplete if only allowed to cool to room temperature. By taking the part down to cryogenic temperatures a more complete stress relief is achieved. Also, cryogenic treatment can compact and tighten the crystalline structure of the metal which improves the toughness and wear resistance of the metal. Cryo treating can also help extend the life of the gears when heavily loaded similar to shot peening by through a different approach.

Microfinishing is essentially a polishing of the gear surfaces. The process we subject our RA and STi gearsets to is a chemical-mechanical process that leaves the gear surfaces nearly mirror smooth without no measurable removal of material. This eliminates the need to break in the gears. It also reduces frictional losses between the gears and reduces the heat generated by the transmission. It can also improve fatigue life by eliminating micro-welding and pitting of the gear surfaces which can be a starting point for surface cracks.

--Dave

Rallispec, Ltd.